navigation

日本NACHI不二越柱塞泵PVS-0A-8N3-30

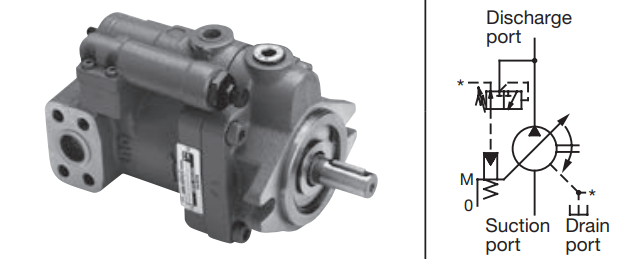

Design No. 30 is applied on PVS-0B to make the pump more compact and lighter, and reduce noise. Production of PVS-3B has been discontinued. Use PZS-3B. Pressure adjustment 3 type has been added to PVS-1B-22 and PVS-2B-45. (Design No. 20 is applied only onPVS-2B-45*3.)FeaturesSpecificationsModel No. Volumecm3/revDischarge volume at no-load ℓ/minPressureadjustment rangeMPa{kgf/cm2}PermittedpeakpressureMPa{kgf/cm2}Rotating speed min-1 Masskg1000min-1 1200min-1 1500min-1 1800min-1 Min. Max.PVS-0B-8*0-301238.0(3.0 to 8.0)8.0 9.6 12.0 14.42 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 7.7PVS-1B-16*0-(*)-1212316.5(5.0 to 16.5)16.5 19.8 24.7 29.72 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 10.5PVS-1B-22*0-(*)-1212322.0(7.0 to 22.0)22.0 26.4 33.0 39.62 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 10.5PVS-2B-35*0-(*)-1212335.0(8.0 to 35.0)35.0 42.0 52.5 63.02 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 21PVS-2B-45*0-(*)-12123-(*)-2045.0(11.0 to 45.0)45.0 54.0 67.5 81.02 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 21Note) Direction of rotation is clockwise when viewed from the shaft end.•Handling•Cautions during Pump Installationand PipingzUse flexible couplings for connectingthe pump shaft to the drive shaft, andprevent a radial or thrust load from being applied on the pump shaft.xFor centering of the pump shaft, limitthe eccentricity between the drive shaftand hydraulic pump shaft to 0.05 mm,and keep the angle error within 1°.cSet the length of insertion between coupling and hydraulic pump shafts so thatit is within at least 2/3 or more of thecoupling width.vUse a sufficiently rigid pump mountingbase.bSet the pressure on the pump suctionside to -0.03 MPa or more (suction portflow velocity within 2 m/sec).nRaise part of the drain piping to abovethe topmost part of the pump body, andinsert the return section of the drainpiping into the hydraulic fluid. Also, observe the values in the following table tolimit the drain back pressure to 0.1 MPa.ModelNo.ItemPVS-0BPVS-1B PVS-2BPipe joint size 3/8" or more 1/2" or morePipe I.D φ7.6 diaormore φ12 dia ormorePipe length 1m or less 1m or lessmMount the pump so the pump shaft isoriented horizontally.•Management of Hydraulic Operating FluidzUse good-quality hydraulic operatingfluid, and use within a kinematic viscosity range of 20 to 200 mm2/sec duringoperation. Use an R&O type and anti-wear hydraulic fluid of ISO-VG32 to68. The optimum kinematic viscosityduring operation is 20 to 50 mm2/sec.xThe operating temperature range is 5 to60°C. When the oil temperature at startup is 5°C or less, warm up the hydraulicpump by low-pressure, low-operationspeed operation until the oil temperature reaches 5°C.cProvide a suction strainer with a filtering grade of about 100μm (150 mesh).Besure to provide a return line filter ofgrade 20μm or less on the return lineto the tank. (When the hydraulic pumpis used at ahigh pressure of 14 MPa ormore, we recommend providing a filterof 10μm or less.vManage the hydraulic operating fluidso that contamination is maintained atclass NAS10 or lower.bUse hydraulic operating fluid within anoperating ambient temperature of 0 to60°C.(continued on following page)Energy-saving Type withDrastically Reduced LossA NACHI-proprietary semi-circular barrel swash plate that receives pressureon its surface ensures a stable discharge volume at all times. This eliminates excessdischarge volume, and enables the effective use of power corresponding tothe load cycle.This "energy-saving type" conservesenergy, reduces power loss, and helpsto reduce hydraulic costs.Silent Type That Demonstrates Its Power QuietlyProprietary low-noise mechanisms areincorporated on the shoe, swash plate,valve plate, and other locations to ensure silent operation. In particular, asemi-circular barrel swash plate stabilizes operation characteristics to ensuresilent operation.

Design No. 30 is applied on PVS-0B to make the pump more compact and lighter, and reduce noise. Production of PVS-3B has been discontinued. Use PZS-3B. Pressure adjustment 3 type has been added to PVS-1B-22 and PVS-2B-45. (Design No. 20 is applied only onPVS-2B-45*3.)FeaturesSpecificationsModel No. Volumecm3/revDischarge volume at no-load ℓ/minPressureadjustment rangeMPa{kgf/cm2}PermittedpeakpressureMPa{kgf/cm2}Rotating speed min-1 Masskg1000min-1 1200min-1 1500min-1 1800min-1 Min. Max.PVS-0B-8*0-301238.0(3.0 to 8.0)8.0 9.6 12.0 14.42 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 7.7PVS-1B-16*0-(*)-1212316.5(5.0 to 16.5)16.5 19.8 24.7 29.72 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 10.5PVS-1B-22*0-(*)-1212322.0(7.0 to 22.0)22.0 26.4 33.0 39.62 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 10.5PVS-2B-35*0-(*)-1212335.0(8.0 to 35.0)35.0 42.0 52.5 63.02 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 21PVS-2B-45*0-(*)-12123-(*)-2045.0(11.0 to 45.0)45.0 54.0 67.5 81.02 to 3.5 {20.4 to 35.7}2 to 7 {20.4 to 71.4}3 to 14 {30.6 to 143 }3 to 21 {30.6 to 214 }25{255}500 2000 21Note) Direction of rotation is clockwise when viewed from the shaft end.•Handling•Cautions during Pump Installationand PipingzUse flexible couplings for connectingthe pump shaft to the drive shaft, andprevent a radial or thrust load from being applied on the pump shaft.xFor centering of the pump shaft, limitthe eccentricity between the drive shaftand hydraulic pump shaft to 0.05 mm,and keep the angle error within 1°.cSet the length of insertion between coupling and hydraulic pump shafts so thatit is within at least 2/3 or more of thecoupling width.vUse a sufficiently rigid pump mountingbase.bSet the pressure on the pump suctionside to -0.03 MPa or more (suction portflow velocity within 2 m/sec).nRaise part of the drain piping to abovethe topmost part of the pump body, andinsert the return section of the drainpiping into the hydraulic fluid. Also, observe the values in the following table tolimit the drain back pressure to 0.1 MPa.ModelNo.ItemPVS-0BPVS-1B PVS-2BPipe joint size 3/8" or more 1/2" or morePipe I.D φ7.6 diaormore φ12 dia ormorePipe length 1m or less 1m or lessmMount the pump so the pump shaft isoriented horizontally.•Management of Hydraulic Operating FluidzUse good-quality hydraulic operatingfluid, and use within a kinematic viscosity range of 20 to 200 mm2/sec duringoperation. Use an R&O type and anti-wear hydraulic fluid of ISO-VG32 to68. The optimum kinematic viscosityduring operation is 20 to 50 mm2/sec.xThe operating temperature range is 5 to60°C. When the oil temperature at startup is 5°C or less, warm up the hydraulicpump by low-pressure, low-operationspeed operation until the oil temperature reaches 5°C.cProvide a suction strainer with a filtering grade of about 100μm (150 mesh).Besure to provide a return line filter ofgrade 20μm or less on the return lineto the tank. (When the hydraulic pumpis used at ahigh pressure of 14 MPa ormore, we recommend providing a filterof 10μm or less.vManage the hydraulic operating fluidso that contamination is maintained atclass NAS10 or lower.bUse hydraulic operating fluid within anoperating ambient temperature of 0 to60°C.(continued on following page)Energy-saving Type withDrastically Reduced LossA NACHI-proprietary semi-circular barrel swash plate that receives pressureon its surface ensures a stable discharge volume at all times. This eliminates excessdischarge volume, and enables the effective use of power corresponding tothe load cycle.This "energy-saving type" conservesenergy, reduces power loss, and helpsto reduce hydraulic costs.Silent Type That Demonstrates Its Power QuietlyProprietary low-noise mechanisms areincorporated on the shoe, swash plate,valve plate, and other locations to ensure silent operation. In particular, asemi-circular barrel swash plate stabilizes operation characteristics to ensuresilent operation.

所有产品分类

所有产品分类

友情链接Link

友情链接Link