navigation

日本美蓓亚NMB应变片FR-1A12L50W05MS/PRJ-5MP-3M-CP/TMNR-500NM

日本NMB美蓓亚MINEBEA扭矩传感器TMNR-500NM议价

议价日本美蓓亚重量控制器CSD-918B-EX

议价日本Minebea美蓓亚压力转换器PRJ-5MP-3M-CP

议价日本Minebea美蓓亚信号放大器CSA-561C

议价日本Minebea美蓓亚主轴放大器OPT-563B

议价日本美蓓亚NMB应变片FR-1A12L50W05MS

议价日本NMB美蓓亚控制线TMNR-ME-10M

议价日本NMB美蓓亚测量应变片J-1-12L30+05WS

议价日本美蓓亚NMB小型压缩式传感器LSM-50K-B

议价日本美蓓亚MINEBEA电磁离合器NFHA1.5-008C

议价日本NMB美蓓亚显示仪表控制盘CSD-891B-P15

议价日本NMB美蓓亚称重传感器C2T1-600K-A

议价日本美蓓亚称重传感器U2D1-10K

议价日本美蓓亚传感器CMM1-2T

议价日本美蓓亚压力传感器NS100A-20MP-1231-5M

议价日本NMB美蓓亚U2D1-10K

日本Minebea美蓓亚NMB变送器NS100A-20MP-3232 议价

议价 日本NMB美蓓亚称重传感器C2D1-100K

议价日本MINEBEA美蓓亚离合器MC-50B

日本美蓓亚Minebea变送器NS100A-20MP-3232议价CSA-507B/CSA-561C

议价日本MINEBEA美蓓亚离合器MC-50B/NFHA1.5-008C/CSD-918B-EX

日本美蓓亚MINEBEA扭矩传感器TMNR-500NM议价C2T1-600K-A/CMM1-2T

议价日本NMB美蓓亚控制线TMNR-ME-10M/OPT-563B/CSD-891B-P15

议价日本NMB美蓓亚测量应变片J-1-12L30+05WS/FR-1A12L50W05MS

议价日本NMB美蓓亚称重显示CSD-815B/C2D1-100K/C2D1-100K

日本NMB美蓓亚NS100A-20MP-1231-5M/LSM-50K-B议价PRJ-5MP-3M-CP

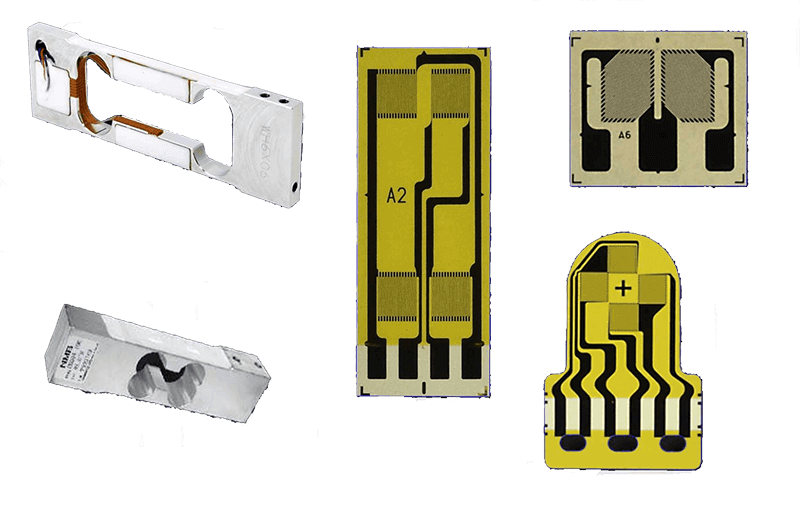

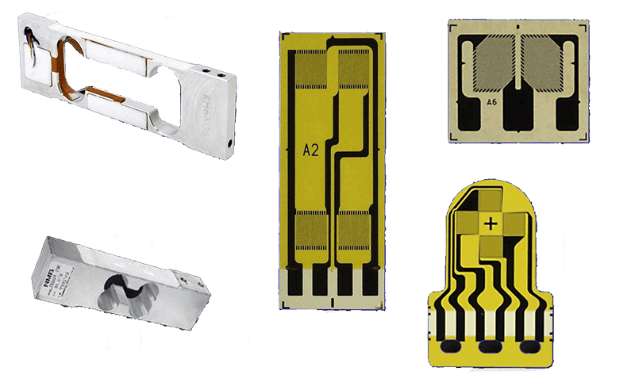

For over 70 years, the Sensing Devices Division of MinebeaMitsumi has been manufacturing high quality measurement components utilizing bonded resistance strain gauge technology. These strain gages are tailored for force, torque, pressure and displacement measurements within industrial, medical, aerospace and consumer industries. Applications range from medical devices, smart phones, commercial scales, tank and vessel weighing, web-tension and bathroom scales.

Features:

High sensitivity

Small footprint

Wide operating temperature range

Low power consumption

Customization and integration support

Applications:

Smartphones and mobile devices

PCs

Gaming

Robotics

Medical devices

Automotive

About Our Strain Gauge Technology

Strain gauges consist of a very thin metallic foil etched in a grid pattern, which is bonded to a device and used to measure the strain when load or pressure is applied. The resulting electrical output is proportional to the strain. Construction of a precise sensing system requires careful selection of gauge material, bonding adhesive, protective coating(s) and lead wires. NMB has a dedicated team of design and application engineers to develop a solution to meet individual customer specifications.

Sensitivity Over 500% Higher

Miniaturization to Less than 1/10 Size

NEW Strain Technology Developed by MinebeaMitsumi

In 2017, MinebeaMitsumi succeeded in developing the Minege product, a new ultra-high sensitivity strain gauge film that demonstrates higher sensitivity (>5X) than conventional materials with a reduced footprint (1/10th). This new film alleviates previous design limitations that restricted the material of the elastic body to which the strain gauge is affixed. In contrast to conventional strain gauges, the Minege material enables new applications with multiple switching functions to support touch force sensitivity in multiple stages. Anticipated applications in the future include human-like touch feedback for robotics and innovative interface solutions for the automotive industry.

Series | Name | Resistive | Base Material | Operating | Strain Limit | Fatigue Limit: | Fatigue Limit: | Operating Temp. |

J | Polyimide foil strain gauge | CuNi foil | Polyimide | -70 ~ 200 | ≥3 mm: 5 ~ 7 | ±1 500 | 10^7 | CN-4: -50 ~ 100 |

J-W | Strain gauge with vinyl wire | CuNi foil | Polyimide | -30 ~ 70 | ≥3 mm: 5 ~ 7 | ±1 500 | 10^7 | CN-4:-50 ~ 70 |

F | Epoxy foil strain gauge | CuNi foil | Special epoxy | -50 ~ 70 | ≥3 mm: 4 | ±1 500 | 10^6 | CN-4:-50 ~ 70 |

F-W | Strain gauge with vinyl wire | CuNi foil | Special epoxy | -30 ~ 70 | ≥3 mm: 4 | ±1 500 | 10^6 | CN-4:-50 ~ 70 |

所有产品分类

所有产品分类

友情链接Link

友情链接Link