navigation

日本共和KYOWA手动测试泵T-300N/(T-300NDX)/T-100K/T-300K

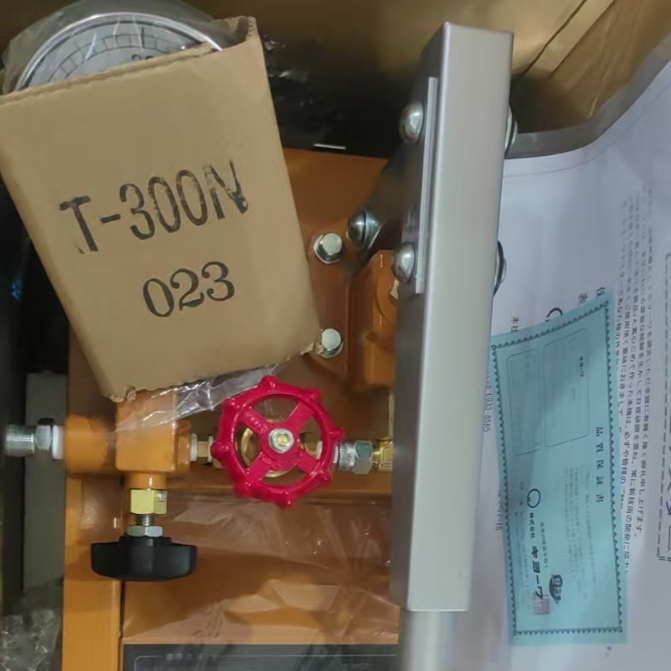

日本共和KYOWA手动测试泵T-300N/(T-300NDX)

■SPECIFICATIONS | |

| MaxpressureMpaPlungerdia.StrokemmSuctionrate/strokec.c.TankvolumlDischargenozzlesizeWeightkgSizeL×H×WAccessoriesT-50N (T-50NDX)5304532.0183/88.0610×375×290Hose ass'y with coupler3/8k×1.5mT-300N (T-300NDX)3012455.0183/88.0610×375×290Hose ass'y3/8k×1mT-500N (T-500NDX)508301.5183/89.5630×410×270Hose ass'yr3/8k×1mT-1000N (T-1000NDX)1008301.5183/59.5630×410×270Hose ass'yr3/8k×1m

| |

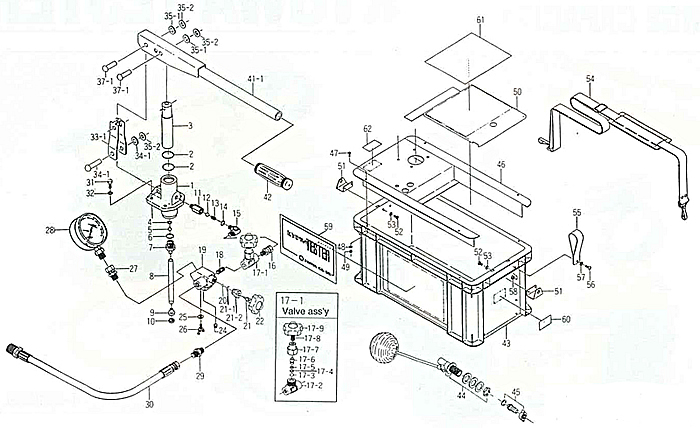

■N-Series CONSTRUCTION | |

| |

| T-50N shown, Configuration differs slightly for T-300N, T-500N and T-1000N. Please be sure to speeify model when you contact us. | |

| No.Part name1Cylinder2O-ring P-303Plunger4Snap ring5Snap ring Suction valve ball 3/86O-ring P-187Suction nipple8Suction pipe9Strainer fitting10Strainer11Suction valve chamber12Suction valve ball 3/813Suction valve spring14O-ring P-1115Suction port elbow 1/416Valve joint 1/417-1Valve ass'y17-2Stop valve substance17-3Valve ball17-4O-ring P-717-5Back up ring17-6Valve ball hold17-7Cap17-8Stop valve shaft17-9Valve handle A18Nipple 1/419Gauge stand20Excluding pressure valve ball 3/621-1Push nut21-2Excluding pressure valve shaft fitting21Excluding pressure valve shaft22Valve handle B24Plug25Flat washer | No.Part name26Bolt27Pressure gauge joint 3/828Pressure gauge j100 φ×35k29Nipple 3/830Anti-pressure hose31Bolt32Flat washer33-1Support34-1Support pin φ12×4535-1Flat washer35-2Speed nut37-1Support pin φ12×4041-1Handle42Grip43Tank(water tank)44Ball tap ass'y45Suction coupling46Pump stand47Small screw48Flat washer49Nut50Tank cover51Hanging fitting52Smal screw53Flat washer54Dangle belt55Handle belt56Small screw57Flat washer58Nut59Main name plate60Equipment name plate61Manyal name plate62Model name plate |

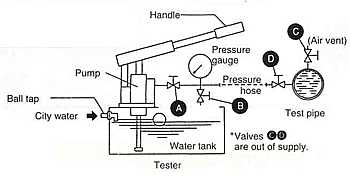

■TESTER INSTALLATION | |

| |

■TESTING PROCEDURE | |

(1) Connest valves C,D to the test pipe. (2) Connect to the valve D with a connecting hose. (3) Feed water into the test pipe from this tester tank or the city water service line, through the vlve D, while purging out the air from valve C.(Feef water till the pipe gets full.) (4) Replenish water into the water tank and then open valves A,B. Thereafter, reciprocate vertically the handle(B) till water begins to come out from the valve B after complete purge-out of the air from the pump. When the water vegan to come out, close the valve B tightly. (5) Open the valve D and feed water from the tester till water begins to flow out from the valvw C, subsequent to purge-out of the air. When water began to flow out, close the valve C tightly. (6) When the specified pressure is reached, close the valve A tightly. ●At this time, pressure is reached, close the valve A tightly. Reversely, no-drop of pressure will show that the test pipe passes the pressure test. (7) After the test, release the applied pressure through the valve B. ●When continuous water feed is required, connect the ball tap to city water service line. | |

所有产品分类

所有产品分类

友情链接Link

友情链接Link