栏目导航

navigation

日本MIKI PULLEY三木电磁离合器111-25-11G

发布时间:2024-10-12

日本MIKI PULLEY三木电磁离合器111-25-11G

111 Models (brakes) Specifications

111 Models

[Specifications]

| Model | Size | Dynamic friction torque Td [N・m] | Static friction torque Ts [N・m] | Coil (at 20℃) | Heat resistance class | Lead wire | Max. rotation speed [min-1] | Armature Moment of inertia J [kg·m2] | Total work performed until readjustment of the air gap ET [J] | Armature pull-in time ta [s] | Torque rise time tp [s] | Torque extinction time td [s] | Mass [kg] | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage [V] | Wattage [W] | Current [A] | Resistance [Ω] | UL style | Size | ||||||||||||

| 111-06-13G | 06 | 5 | 5.5 | DC24 | 11 | 0.46 | 52 | B | UL3398 | AWG22 | 8000 | 4.23×10-5 | 36×106 | 0.015 | 0.033 | 0.015 | 0.28 |

| 111-06-12G | 06 | 5 | 5.5 | DC24 | 11 | 0.46 | 52 | B | UL3398 | AWG22 | 8000 | 6.03×10-5 | 36×106 | 0.015 | 0.033 | 0.015 | 0.32 |

| 111-06-11G | 06 | 5 | 5.5 | DC24 | 11 | 0.46 | 52 | B | UL3398 | AWG22 | 8000 | 6.03×10-5 | 36×106 | 0.015 | 0.033 | 0.015 | 0.32 |

| 111-08-13G | 08 | 10 | 11 | DC24 | 15 | 0.63 | 38 | B | UL3398 | AWG18 | 6000 | 1.18×10-4 | 60×106 | 0.016 | 0.042 | 0.025 | 0.5 |

| 111-08-12G | 08 | 10 | 11 | DC24 | 15 | 0.63 | 38 | B | UL3398 | AWG18 | 6000 | 1.71×10-4 | 60×106 | 0.016 | 0.042 | 0.025 | 0.58 |

| 111-08-11G | 08 | 10 | 11 | DC24 | 15 | 0.63 | 38 | B | UL3398 | AWG18 | 6000 | 1.71×10-4 | 60×106 | 0.016 | 0.042 | 0.025 | 0.58 |

| 111-10-13G | 10 | 20 | 22 | DC24 | 20 | 0.83 | 29 | B | UL3398 | AWG18 | 5000 | 4.78×10-4 | 130×106 | 0.018 | 0.056 | 0.030 | 0.91 |

| 111-10-12G | 10 | 20 | 22 | DC24 | 20 | 0.83 | 29 | B | UL3398 | AWG18 | 5000 | 6.63×10-4 | 130×106 | 0.018 | 0.056 | 0.030 | 1.07 |

| 111-10-11G | 10 | 20 | 22 | DC24 | 20 | 0.83 | 29 | B | UL3398 | AWG18 | 5000 | 6.63×10-4 | 130×106 | 0.018 | 0.056 | 0.030 | 1.07 |

| 111-12-13G | 12 | 40 | 45 | DC24 | 25 | 1.04 | 23 | B | UL3398 | AWG18 | 4000 | 1.31×10-3 | 250×106 | 0.027 | 0.090 | 0.050 | 1.68 |

| 111-12-12G | 12 | 40 | 45 | DC24 | 25 | 1.04 | 23 | B | UL3398 | AWG18 | 4000 | 1.81×10-3 | 250×106 | 0.027 | 0.090 | 0.050 | 1.97 |

| 111-12-11G | 12 | 40 | 45 | DC24 | 25 | 1.04 | 23 | B | UL3398 | AWG18 | 4000 | 1.81×10-3 | 250×106 | 0.027 | 0.090 | 0.050 | 1.97 |

| 111-16-13G | 16 | 80 | 90 | DC24 | 35 | 1.46 | 16 | B | UL3398 | AWG18 | 3000 | 4.80×10-3 | 470×106 | 0.035 | 0.127 | 0.055 | 3.15 |

| 111-16-12G | 16 | 80 | 90 | DC24 | 35 | 1.46 | 16 | B | UL3398 | AWG18 | 3000 | 6.35×10-3 | 470×106 | 0.035 | 0.127 | 0.055 | 3.45 |

| 111-16-11G | 16 | 80 | 90 | DC24 | 35 | 1.46 | 16 | B | UL3398 | AWG18 | 3000 | 6.35×10-3 | 470×106 | 0.035 | 0.127 | 0.055 | 3.45 |

| 111-20-13G | 20 | 160 | 175 | DC24 | 45 | 1.88 | 13 | B | UL3398 | AWG16 | 2500 | 1.37×10-2 | 10×108 | 0.065 | 0.200 | 0.070 | 5.9 |

| 111-20-12G | 20 | 160 | 175 | DC24 | 45 | 1.88 | 13 | B | UL3398 | AWG16 | 2500 | 1.90×10-2 | 10×108 | 0.065 | 0.200 | 0.070 | 7.1 |

| 111-20-11G | 20 | 160 | 175 | DC24 | 45 | 1.88 | 13 | B | UL3398 | AWG16 | 2500 | 1.90×10-2 | 10×108 | 0.065 | 0.200 | 0.070 | 7.1 |

| 111-25-13G | 25 | 320 | 350 | DC24 | 60 | 2.5 | 9.6 | B | UL3398 | AWG16 | 2000 | 3.58×10-2 | 20×108 | 0.085 | 0.275 | 0.125 | 10.5 |

| 111-25-12G | 25 | 320 | 350 | DC24 | 60 | 2.5 | 9.6 | B | UL3398 | AWG16 | 2000 | 4.83×10-2 | 20×108 | 0.085 | 0.275 | 0.125 | 12.2 |

| 111-25-11G | 25 | 320 | 350 | DC24 | 60 | 2.5 | 9.6 | B | UL3398 | AWG16 | 2000 | 4.83×10-2 | 20×108 | 0.085 | 0.275 | 0.125 | 12.2 |

*The dynamic friction torque, Td, is measured at a relative speed of 100 min-1. Depending on the initial torque characteristics, break-in to condition the engaging surfaces may also be required.

*The rotating part moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

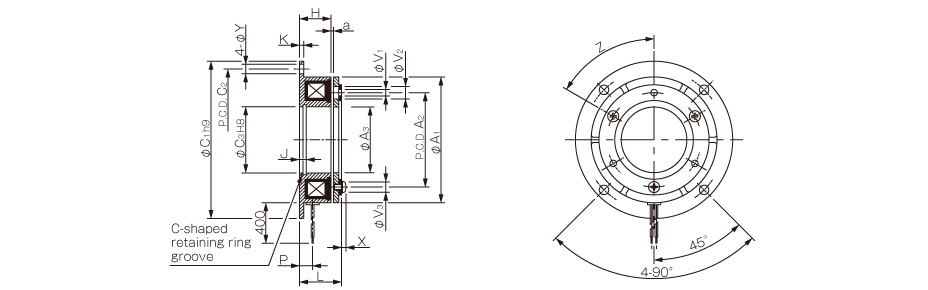

111-□-13G

Unit [mm]

| Size | Radial direction dimensions | Axial direction dimensions | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | C1 | C2 | C3 | V1 | V2 | V3 | Y | Z | H | J | K | L | P | X | a | ||

| 06 | 63 | 46 | 34.5 | 80 | 72 | 35 | 3-3.1 | 3-6.3 | 3-5.5 | 5 | 6-60° | 18 | 3.5 | 2.1 | 22 | 7.3 | 2.5 | 0.2±0.05 | |

| 08 | 80 | 60 | 41.7 | 100 | 90 | 42 | 3-4.1 | 3-8 | 3-7 | 6 | 6-60° | 20 | 4.3 | 2.6 | 24.5 | 8.3 | 2.85 | 0.2±0.05 | |

| 10 | 100 | 76 | 51.5 | 125 | 112 | 52 | 3-5.1 | 3-11 | 3-9 | 7 | 6-60° | 22 | 5 | 3.1 | 28.1 | 9 | 3.3 | 0.2±0.05 | |

| 12 | 125 | 95 | 61.5 | 150 | 137 | 62 | 3-6.1 | 3-12 | 3-11 | 7 | 6-60° | 24 | 5.5 | 3.6 | 31 | 9.3 | 3.3 | 0.3+0.05-0.1 | |

| 16 | 160 | 120 | 79.5 | 190 | 175 | 80 | 3-8.2 | 3-15 | 3-14 | 9.5 | 6-60° | 26 | 6 | 4.1 | 35 | 11.7 | 3.5 | 0.3+0.05-0.1 | |

| 20 | 200 | 158 | 99.5 | 230 | 215 | 100 | 3-10.2 | 3-18 | 3-16.2 | 9.5 | 6-60° | 30 | 7 | 5.1 | 41.4 | 13.4 | 4.9 | 0.50-0.2 | |

| 25 | 250 | 210 | 124.5 | 290 | 270 | 125 | 4-12.2 | 4-22 | 4-20 | 11.5 | 8-45° | 35 | 8 | 6.1 | 47.9 | 16 | 5.5 | 0.50-0.2 | |

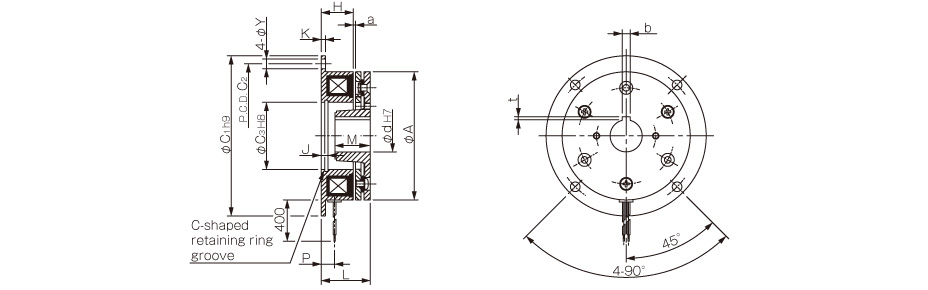

[Dimensions]

111-□-12G

所有产品分类

所有产品分类

友情链接Link

友情链接Link